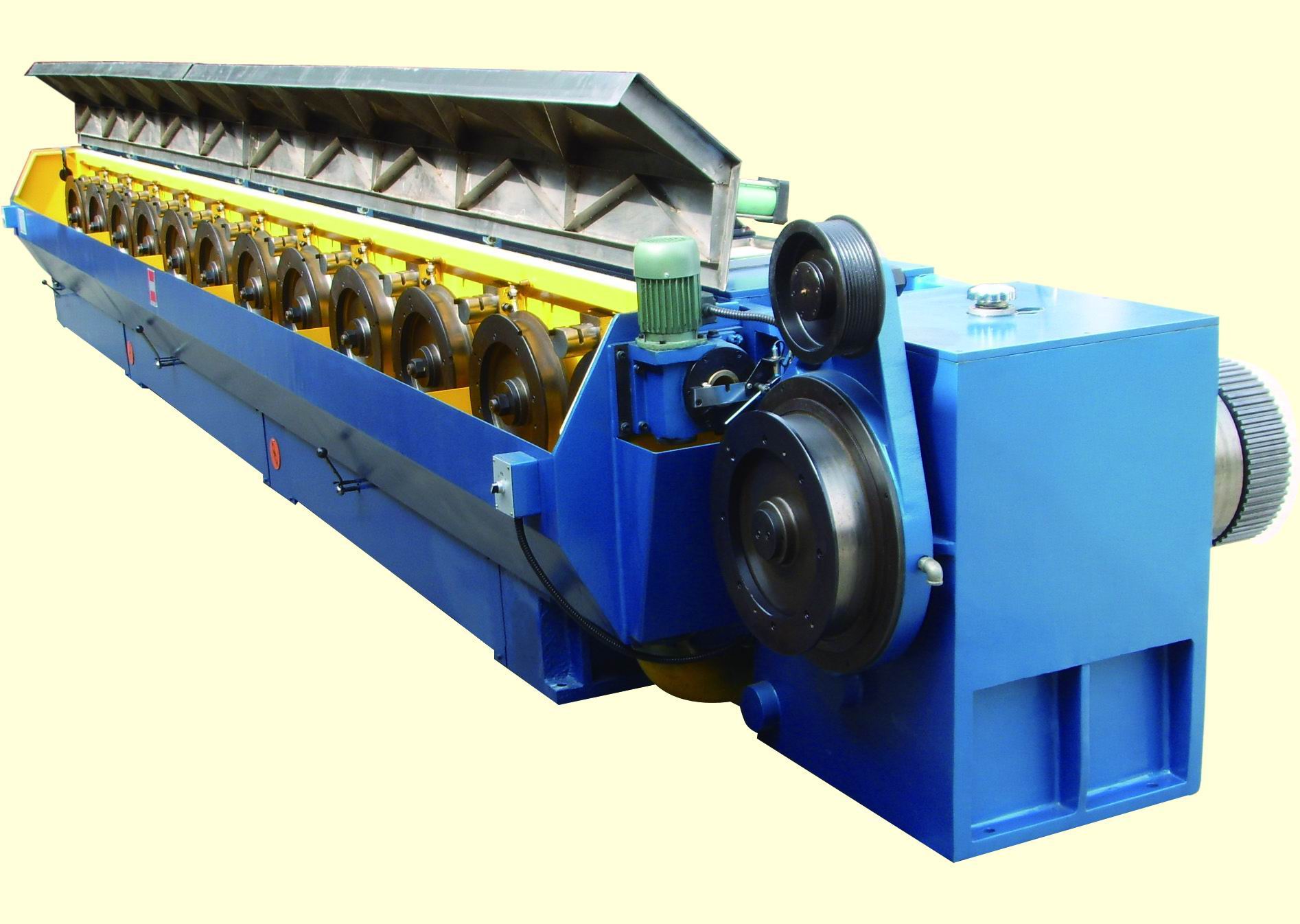

HLC—450/13型連續(xù)退火銅大拉 Continuous Annealing Copper Rod Breakdown Machine 本機(jī)供電線(xiàn)電纜廠拉制φ1.2~φ3.5的圓銅線(xiàn),可拉制硬銅線(xiàn)和連續(xù)退火軟銅線(xiàn)。本機(jī)拉線(xiàn)鼓輪采用串列式排列,定速輪和其它12道拉線(xiàn)鼓輪分別由二臺(tái)直流電機(jī)拖動(dòng),可進(jìn)行快速換模,極大地方便了操作。 This machine is made for producing φ1.2~φ3.5 round-shaped copper wire for the wire and cable factory.the drawing capstan are arranged in tandem ,finish capstan and other 12 drawing capstans are seperately dragged by 2 DC machines.This can change the mould fast and make the operation simpler to a large extent. 電控系統(tǒng)采用西門(mén)子裝置,數(shù)字通訊,全線(xiàn)PLC控制,人機(jī)界面。 The electrical control is installed with the original Siemens control system,all lines are PLC controlled and human-computer interface 本機(jī)收線(xiàn)可配置雙盤(pán)自動(dòng)收線(xiàn)裝置及成圈下線(xiàn)裝置。 The Drawing of this machine can be equipped with dual auto take-up device and coiler take-up device.

一、設(shè)備簡(jiǎn)述 brief introduction to the equipment

本機(jī)供電線(xiàn)電纜廠拉制φ1.2~φ3.5的圓銅線(xiàn),可拉制硬銅線(xiàn)和連續(xù)退火軟銅線(xiàn)。本機(jī)拉線(xiàn)鼓輪采用串列式排列,定速輪和其它12道拉線(xiàn)鼓輪分別由二臺(tái)直流電機(jī)拖動(dòng),可進(jìn)行快速換模,極大地方便了操作。

This machine is made for producing φ1.2~φ3.5 round-shaped copper wire for the wire and cable factory.the drawing capstan are arranged in tandem ,finish capstan and other 12 drawing capstans are seperately dragged by 2 DC machines.This can change the mould fast and make the operation simpler to a large extent.

電控系統(tǒng)采用西門(mén)子裝置,數(shù)字通訊,全線(xiàn)PLC控制,人機(jī)界面。

The electrical control is installed with the original Siemens control system,all lines are PLC controlled and human-computer interface

本機(jī)收線(xiàn)可配置雙盤(pán)自動(dòng)收線(xiàn)裝置及成圈下線(xiàn)裝置。

The Drawing of this machine can be equipped with dual auto take-up device and coiler take-up device.

二、主要技術(shù)參數(shù)main technical parameters

1、進(jìn)線(xiàn)直徑inline wire Dia. max. φ8 mm

2、出線(xiàn)直徑 outlet wire Dia. max. φ1.2~φ3.5 mm

3、拉線(xiàn)、退火速度 drawing,annealing spped max 25 m/s

4、拉伸道次 number of drafts max 13 道

5、拉線(xiàn)鼓輪直徑(等直徑)

Dia. of drawing capstan (equal Dia.) φ450 mm

6、最大模具尺寸 Max. mould size φ43×35 mm

7、成圈收線(xiàn)容量 coiler take-up volume 2 t

收線(xiàn)范圍 take-up range φ3.5~φ1.6 mm

收線(xiàn)速度 take-up speed max. 15 m/s

8、雙盤(pán)收線(xiàn)盤(pán)規(guī)格 type of dual take-up PND630 PND500

9、最大退火電流 Max.annealing curent 6000 A

10、最大退火電壓 Max.annealing voltage 55 V

11、拉線(xiàn)主電機(jī) drawing host

型號(hào) type Z4-315-12

功率 power 280 kw

12、定速輪電機(jī) electric machine of finish capstan

型號(hào) type Z4-200-21

功率 power 75 kw

13、雙盤(pán)收線(xiàn)電機(jī) dual take-up motor

型號(hào) type Z4-160-31

功率 power 30x2 kw

14、主機(jī)潤(rùn)滑油泵 oil pump of host lubrication

CBZ-50 50L/min 3 kw

15、儲(chǔ)線(xiàn)裝置儲(chǔ)線(xiàn)長(zhǎng)度

Wire length in accumulator max. 約5.2 m

16、儲(chǔ)線(xiàn)輪最大行程 max. stroke of accumulator ring 840 mm

17、使用壓縮空氣壓力(氣源用戶(hù)自理)pressure of required compressed air

(the air source are resolved by the buyer) 0.4~0.6 Mpa

18、電蒸汽爐加熱功率 lectric vapour heating power 9 kw

三、設(shè)備組成equipment comprises:

1、放線(xiàn)架 pay-off stand 1套

2、拉線(xiàn)機(jī)主機(jī)(包括主電機(jī)、定速輪電機(jī)) 1套

host of wire drawing (including electric host and finish capstan electric host)

3、連續(xù)退火裝置 1套

Continuous annealing device

4、儲(chǔ)線(xiàn)裝置 accumulator 1套

5、雙盤(pán)收線(xiàn)裝置 dual take-up device 1套

6、成圈收線(xiàn)裝置 coiler take-up deivce 1套

7、拉線(xiàn)主機(jī)潤(rùn)滑裝置 drawing host lubrication device 1套

8、軋頭穿模機(jī) wire pointer and stripper 1套

9、電氣控制柜 electric control cabinet 1套

10、電蒸爐 electric vapour furnace 1套

四、設(shè)備技術(shù)特點(diǎn)characteristics of equipment

1、拉線(xiàn)牙箱整體鑄造,與分體拼結(jié)結(jié)構(gòu)相比,剛性大大提高,不會(huì)變形,密封性好,不會(huì)產(chǎn)生漏水、漏油等現(xiàn)象。

Xx is founded in whole*,compare with being founded seperately,the xx has been enhanced and it’s not easily transfigurable,it’s leak-free from water, oil etc.

2、拉線(xiàn)機(jī)采用高性能斜齒輪傳動(dòng),全方位加工。高速檔齒輪齒面淬火磨齒。拉線(xiàn)鼓輪采用中碳鋼基體,表面噴涂碳化鎢。

Wire stretcher is equipped with high-qualified inclining gear transmission,omnidirectionally processed. High-gear is quenched and the drawing capstan is made of medium carbon steel matrix with tungsten carbide sprayed on the surface

3、采用半浸沒(méi)式潤(rùn)滑冷卻方式,確保線(xiàn)材和拉線(xiàn)模有效的冷卻和潤(rùn)滑

Cooling adoption of semi-dipping lubrication ensures the wire and the mould being cooled and lubricatd efficiently.

4、退火裝置設(shè)計(jì)為傾斜式,降低了高度,操作方便。專(zhuān)門(mén)設(shè)計(jì)的風(fēng)道使退火輪后部變得十分簡(jiǎn)潔,方便了日常維護(hù)保養(yǎng)。

The annealing device is inclination type and it’s easy to operate because of the lowered height. The design of airway makes the back of fire-ring more simple and convenient for maintenace.

5、雙盤(pán)收線(xiàn)設(shè)計(jì)先進(jìn)可靠,有關(guān)傳動(dòng)部分均進(jìn)行動(dòng)平衡校正,采用氣動(dòng)系統(tǒng)及電氣通訊方式控制換盤(pán),穩(wěn)定性好,捕捉成功率高。由于采用氣動(dòng)控制,工作場(chǎng)地整潔干凈,解決了選用液壓系統(tǒng)可能產(chǎn)生的漏油現(xiàn)象。

Dual take-up design is advanced and transmission parts are dynamic balancing emendated,using a air-started system and electric communication to control the changer is good for stablity and a high success rate of capture.because of the air-starting control,the workplace can be tidy and clean ,this solved the oil-leaking problem of liquid pressure system.

6、拉線(xiàn)主機(jī)、定速輪、成圈收線(xiàn)及雙盤(pán)收線(xiàn)電機(jī)均采用原裝西門(mén)子控制器,全線(xiàn)PLC控制,采用進(jìn)口人機(jī)界面,能方便地發(fā)出操作指令,察看整機(jī)運(yùn)行狀況,調(diào)整工藝參數(shù),并具有故障診斷功能。

Drawing host, finish capstan,coiling take-up and dual drawing motor are all imported from Siemens,all line PLC controlled with a human-computer interface.This makes the command and adjust of running situationa and parameters easy,and it is error-detection possible.

7、定速輪內(nèi)設(shè)有水冷或風(fēng)冷機(jī)構(gòu),可有效降低拉線(xiàn)時(shí)定速輪溫度。

Finish capstan has a water-cooling or wind-cooling device,can cool of the capstan while drawing.